3 min read

Embracing a Sustainable Future: COP28 Insights

COP28 - the 28th annual United Nations Climate Change Conference - was a major global summit which took place in Dubai...

Reduce energy consumption and related costs. Understand – in detail – the energy costs of your manufacturing processes with our easy-to-use energy monitoring platform.

In the fast-paced world of manufacturing, staying ahead depends on optimizing every aspect of your operations.

When it comes to reducing energy consumption, it is essential to understand where your energy is being consumed, how much and when.

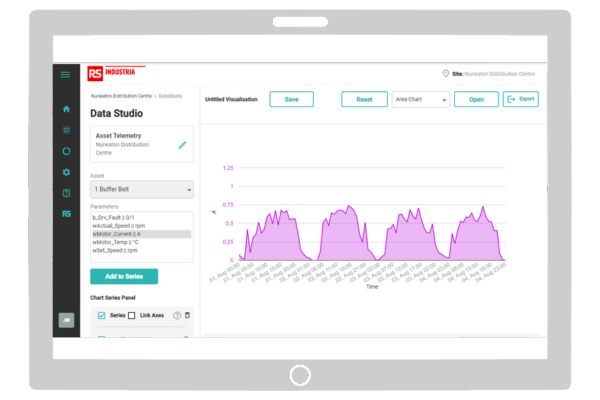

RS Industria is an industrial data platform that gives you the option to collect energy data on an asset-by-asset, line-by-line, or plant-by-plant basis.

Allowing you to make informed decisions on where you can have the greatest impact on your overall energy consumption.

Our solution has allowed manufacturers like Whitby Seafoods to gain real-time insights into energy usage across their manufacturing plants. Highlighting areas of waste or inefficiency, RS Industria customers have been able to make data-driven changes that have resulted in initial savings of around £24k per site in the first year.

As energy continues to be a significant expense for manufacturers, opportunities to lower consumption and therefore reduce costs need to be investigated. Real-time energy monitoring not only gives you the data you need to spot trends and patterns in consumption, it also allows you to make fast and informed decisions on equipment usage, production scheduling and energy-saving initiatives.

Manufacturers are coming under increasing pressure to reduce their carbon footprint, while still maintaining overall operating efficiency. RS Industria customers have already made significant steps towards their sustainability goals, using real-time data from our platform alongside the advice of our Customer Success team and Solution Engineers, they have been able to implement energy-saving initiatives within weeks of using the platform.

Our RS Industria customers are already using our energy monitoring solution to help identify potential critical failures on key assets before they happen. Changes in energy patterns are often key indicators of equipment malfunctions or inefficiencies due to worn or broken components. For customers RS Industria customers the data has proved invaluable in improving productivity, reducing waste and improving overall operational efficiency.

Customers monitoring their energy have also utilised real-time data extracted by the RS Industria solution to streamline their operations and improve their overall efficiency. Changes in patterns in energy consumption have identified bottlenecks, assisted in optimising workflows and eliminated energy-draining inefficiencies.

RS Industria is quick and easy to install allowing you to implement energy-saving initiatives fast.

.png?width=600&height=400&name=Energy%20Dashboard%20Laptop%20(1).png)

RS Industria modular approach to asset monitoring gives you the flexibility to choose what to monitor and when.

Jan 17, 2024 by RS Industria

COP28 - the 28th annual United Nations Climate Change Conference - was a major global summit which took place in Dubai...

Dec 20, 2023 by RS Industria

The Net Zero clock is ticking and moves to improve energy efficiency in UK manufacturing are gathering pace. According...

Sep 29, 2023 by RS Industria

As Net Zero approaches, the pressure on industry to deliver on sustainability targets increases, and this is compounded...

The RS Industria platform enabled us to connect all our existing meters relatively easily and we were able to add some additional ones and, very quickly, we were able to get a comprehensive view of how we’re using our electricity by hour, by minute, by second, across the site.

Using RS Industria has allowed us to view our real-time energy consumption and drive improvement using very basic initiatives and routines, without any investment outside of the platform itself, purely by having visibility and allowing us to answer the question “is what we are doing making a difference?