The Benefits

Rapid Time To Value

Impactful savings were achieved within weeks, while its modular nature can be further utilised to deliver longer-term success.

Delivers Greater Visibility and Control

Continuous monitoring of assets delivers valuable insight into site, line, and asset consumption, with 49 locations now under

real-time scrutiny across Whitby Seafoods’ operations.

Drives Down Usage and Waste

RS Industria tracks usage in real-time, with resulting data analysis used to action changes.

Encourages Energy-Saving Behaviours

Insight can be leveraged to encourage energy-saving cultures and achieve corporate sustainability goals.

The Problem

The recent volatility in the price of energy combined with the pressing need to reduce carbon emissions has turned up the heat for UK manufacturers.

For Whitby Seafoods, a desire to reduce its impact on the environment has led to a drive to improve the sustainability of its ingredients and deliver transparency of its carbon footprint.

An overview of consumption at the company’s manufacturing site was proving challenging, however. With no insight or ability to understand how much energy was being used and where losses were occurring, engineers looking to drive down consumption and reduce waste needed help, and fast.

The Solution

RS Industria digitally connects assets to deliver data that can be leveraged to reduce energy consumption, saving customers time and money.

Monitoring energy usage to drive out costly waste is just one of a series of game-changing benefits that RS Industria delivers, with the solution in use across a range of industries to enhance yield, reduce downtime and increase the productivity of people and plant.

Working together with RS, Whitby Seafood’s engineers have been able to use RS Industria’s continuous monitoring capabilities to drive tangible savings and deliver clear reductions in energy usage across its site.

Before implementing the solution, RS worked with the customer to identify a total of 49 energy-intensive assets to be monitored, including machines in the cold store, the ammonia plant room, and the packing and coating lines.

In order to determine kWh and current, sub-metering was installed to show how much energy was being consumed and where with hardware digitally enabling data collection for analysis in the cloud.

By gathering continuous, real-time data, the resulting insight has given Whitby Seafoods greater visibility of variations in individual asset consumption and enabled them to identify where usage can be reduced without affecting productivity or yield.

The Outcome

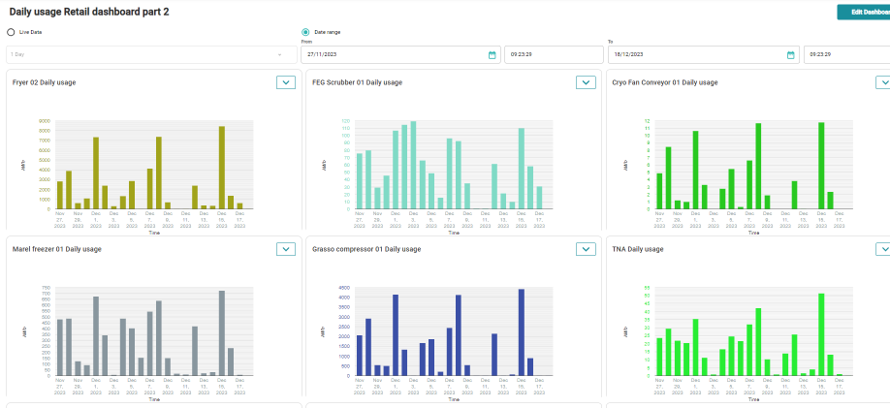

Now, with data visualised on a dashboard, Whitby’s engineers have clear access to information showing how much energy is being consumed daily, weekly and monthly. Alongside insight on variations of usage at different times, such as when the site is running or inactive, Whitby Seafoods has access to the true cost of production.

Within weeks of installation, RS Industria has enabled Whitby’s engineers to identify that the ‘close down’ procedure on a Friday for example was not being executed properly, with data highlighting that two energy intensive assets were being left on over the weekend.

In the case of a fryer, data immediately flagged high consumption when the asset was meant to be in shutdown. Furthermore, high energy levels – equivalent to and sometimes even higher than when the asset was in production mode - were highlighted when the fryer was undergoing its weekly clean.

This insight enabled engineers to immediately investigate how the water heating process used during cleaning

could be better optimised to reduce waste, without compromising on the hygiene standards the business demands.

"Using RS Industria has already resulted in quick wins. We will now be able to look at the data in more detail to see where else we can make better and informed decisions to drive down waste and consumption."

Whitby Seafoods Spokesperson

Next Steps

Using RS Industria to monitor particularly energy intensive assets like the fryer has provided insight that can be turned into immediate action.

For Whitby Seafoods, the natural step is to extend its usage to optimise asset performance and lifespan, using continuous monitoring to reduce downtime and inform a predictive maintenance strategy for greater productivity.