The Benefits

Prevented

Failure

Critical asset protected from potentially catastrophic failure.

Pre-Emptive Sourcing of Components

Long lead time spares sourced in advance.

Avoided Secondary Damage

Potentially serious and costly damage to other parts of the filler avoided.

Early Warning Enabled Planned Response

Maintenance team able to prepare for replacement.

The Problem

With little insight into components critical to the performance of a key asset, Histon engineers faced the very real possibility of costly, unplanned downtime.

Right-angled power transfer boxes are an essential part of the site’s high- speed filling machines. Simple components, which are used extensively by manufacturers as a robust solution for transferring power within a single machine, the transfer box connects the main filler to the blower, ensuring that two key parts of the machine are always synchronised.

The transfer box does however present some maintenance challenges for Histon’s engineers, as they are assembled and sealed when manufactured and can’t be opened up for routine internal inspections. As the boxes don’t generally feature sight glasses, engineers are also unable to view the internal lubricant level.

Transfer boxes are usually located under the filler production line, making external inspection difficult. This has several consequences; if not regularly cleaned, the boxes are usually covered in food debris, which is often corrosive (especially sugary or acidic products), damaging the casing and resulting in lubricant loss.

Another complication is that high-pressure water cleaning can cause ingress of water via the bearing seals, which degrades the internal lubricant, while steam- cleaning also removes visual indication of lubricant leakage or water ingress.

The Solution

Working together with engineering counterparts at the Histon site, the RS Industria team fitted several vibration sensors onto key components within the site’s main filling line, including the two power transfer boxes. This enabled continuous condition monitoring.

The process control system was then digitally connected to the RS Industria data platform, which captured information such as line status, short-stops, and run rate.

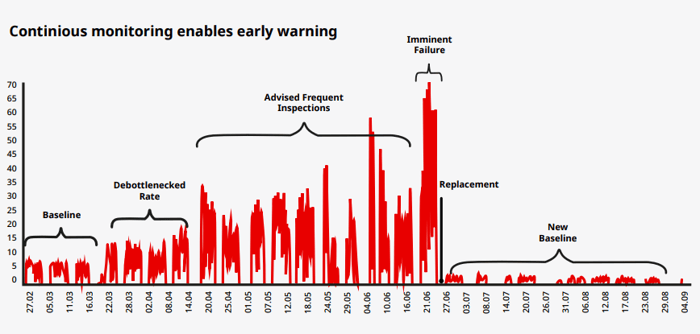

To enable automated alerts to be sent to Histon’s engineers in the event of any issues, vibration levels were baselined within the context of the process control data to set up vibration limits.

Using RS Industria’s unique Stratified Vibration Analysis technique, the customer was able to gain a greater understanding of the condition of the components within the asset and its overall performance.

The Outcome

RS Industria proved its worth within months when it highlighted a significant increase in overall vibration within a specific transfer box. With the increase flagged, the relevant spare components were procured as a precaution.

When vibration levels suddenly increased further a few weeks later, the team was alerted to the potentially imminent failure of the transfer box. The filler was stopped to replace the transfer box quickly and efficiently. Upon dismantling the old transfer box, the bearings were found to be collapsing, the sealed lubricant was contaminated with water and the unit was just hours away from a catastrophic failure – an event that would have caused the filler to be shut down for a minimum of two days.

Following the replacement of the transfer gearbox and the refitting of the vibration sensor, the new monitoring data showed that the filler was now operating within normal limits.

Next Steps

By preventing the failure of a key component, RS Industria was able to save the customer thousands of pounds in urgent repair costs, new components, and lost production.

The monitoring data and alerting functions continue to not only protect this vital asset but generate insight into the operation of the filler, enabling optimisation, and greater efficiency.

The site is looking to extend the RS Industria system to other critical assets in the near future.