1 min read

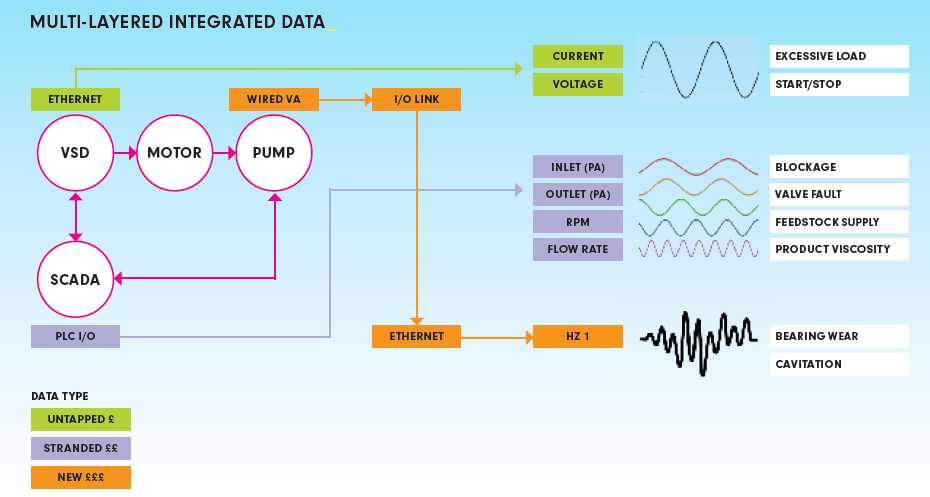

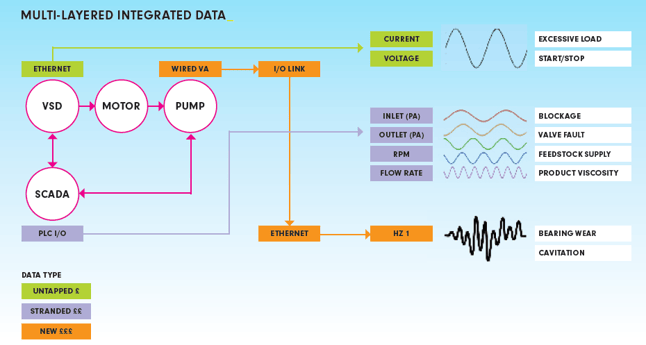

The impression is that collecting and collating this data to create insight is a complex endeavour. In practical terms, a lot of that data is already available or can be easily harvested. So the key challenge is about tapping into that data and collecting it in a structured way.

There are typically three key sources of data in an industrial setting

Existing data flows within factories are often single-purpose ‘vertical’ flows dedicated to a specific process or asset. To unlock the true value of such data flow, it needs to be integrated horizontally with other systems and devices, often being repurposed for different objectives.

This is the true ‘connected factory’.

But of course, IIoT implementation does not necessarily have to start by going big with big data. It can start small with just one application. As opposed to big data, it’s about gathering the right data, and often a little data can go a long way in helping to achieve insight that leads to practical and cost-saving benefits.

RS Industria’s modular platform offers just such a plug-and-play approach to IIoT, enabling users to start with low-cost, low-risk projects that can expand over time.